Ethanol is one of the best tools we have to fight air pollution from vehicles. And there is no fuel available at scale today that matches ethanol’s ability to improve overall environmental quality compared to gasoline. From its biodegradable nature to reductions in greenhouse gas and tailpipe emissions, ethanol provides a tool to address environmental concerns without requiring an entirely new way for goods and people to get from one place to another.

Ethanol contains 35% oxygen. Adding oxygen to fuel results in more complete fuel combustion, reducing harmful tailpipe emissions. Ethanol also displaces the use of toxic gasoline components such as benzene, a carcinogen. Ethanol is non-toxic, water soluble and quickly biodegradable. Ethanol is a renewable fuel produced from plants, unlike petroleum-based fossil fuels that have a limited supply and are the major contributor of carbon dioxide (CO2) emissions, a greenhouse gas (GHG).

FACT: Using ethanol in place of gasoline helps to reduce carbon dioxide (CO2) emissions by an average of 34% compared to gasoline.

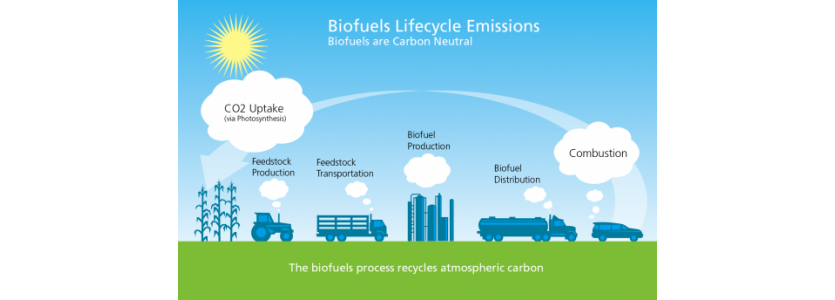

Because ethanol is made from renewable, plant-based feedstocks, the CO2 released during a vehicle’s fuel combustion is “recycled” during the growth of ethanol feedstocks. According to the Department of Energy’s GREET model, average corn ethanol reduces GHG emissions by 34% compared to gasoline – even when hypothetical land use emissions are considered. Without indirect emissions, average corn ethanol decreases GHG emissions by 44%.

FACT: In 2014, the use of ethanol in gasoline reduced CO2-equivalent greenhouse gas emissions from transportation by 39.6 million metric tons. That’s equivalent to removing 8.4 million cars from the road for an entire year.

FACT: New technologies are increasing ethanol yields, improving efficiencies and allowing ethanol biorefineries to make better use of natural resources. Over the past two decades, the industry has dramatically reduced the environmental impacts of producing ethanol. The amount of thermal energy required to make a gallon of ethanol has fallen 36% since 1995, while electricity use is down 38%. At the same time, producers are squeezing 12% more ethanol out of every bushel of corn. Meanwhile, water use has been cut in half since 1998.

FACT: Ethanol has a positive energy balance. Improved ethanol production efficiencies in concert with new farming technologies means that the energy benefits of ethanol continue to grow. According to the latest USDA research, 1 unit of energy invested in the corn ethanol production process results in 2.3 units of usuable energy in the form of ethanol.

FACT: The American Lung Association in Illinois supports the use of E85, a blend of 85% ethanol and 15% gasoline for flex-fuel vehicles specifically designed to operate on this fuel. “E85 vehicles are required to meet the same tailpipe emission standards as other light duty vehicles, however, when using E85, these flex-fuel vehicles may have lower emissions of some pollutants than conventional gasoline-fueled vehicles.”

FACT: Ethanol reduces tailpipe carbon monoxide emissions by as much as 30%, toxics content by 13% (mass) and 21% (potency), and tailpipe fine particulate matter (PM) emissions by 50%. Ethanol also reduces secondary PM formation by diluting aromatic content in gasoline. Over half of the air pollution attributable to vehicles comes from “high emitting” vehicles that make up only 10% of the vehicle fleet. High emitters include older vehicles as well as well as newer cars with malfunctioning pollution control systems. The use of ethanol-blended fuel is also one of the best pollution control strategies for off-road vehicles, including motorcycles, ATVs and snowmobiles, which represent a significant source of emissions. Source: Smog Reyes, February 2004.

FACT: Ethanol is the oxygenate of choice in the federal winter oxygenated fuels program in cities that exceed public health standards for carbon monoxide pollution.

FACT: Ethanol is rapidly biodegraded in surface water, groundwater and soil, and is the safest component in gasoline today.

A study conducted for the Governors’ Ethanol Coalition, “The Fate and Transport of Ethanol-Blended Gasoline in the Environment,” concluded that ethanol poses no threat to surface water and ground water. According to the report, ethanol is a naturally occurring substance produced during the fermentation of organic matter and is expected to rapidly biodegrade in essentially all environments. When gasoline contaminates soil or water, ethanol is the first component to quickly, safely, and naturally biodegrade. A study commissioned by the MTBE industry suggested that in the event of a gasoline spill or leak, since ethanol breaks down first, benzene would persist in the environment longer. But this ignores the fact that ethanol-blended fuels contain less benzene, and the real threat posed to the environment is from the presence of benzene in gasoline, not ethanol.

FACT: Ethanol reduces smog pollution.

Blending ethanol in gasoline dramatically reduces carbon monoxide tailpipe emissions. According to the National Research Council, carbon monoxide emissions are responsible for as much as 20% of smog formation. Additionally, ethanol-blended fuels reduce tailpipe emissions of volatile organic compounds, which readily form ozone in the atmosphere. These reductions more than offset any slight increases of evaporative emissions due to the higher volatility of ethanol-blended fuel. Thus, the use of ethanol plays an important role in smog reduction.

Importantly, in reformulated gasoline areas where smog is of most concern, gasoline blended with ethanol must meet the same evaporative emission standard as gasoline without ethanol. These ethanol blends have the added benefit of providing reduced tailpipe carbon monoxide emissions and, therefore, further emissions reductions of smog.

FACT: Water usage in ethanol production is declining.

Water use has been cut in half since 1998. Water is required to produce most of the energy we consume. For example, a gallon of gasoline requires anywhere from 2.5-8 gallons of water to produce. The use of all natural resources, including water, in ethanol production is an issue the U.S. ethanol industry takes very seriously. That is why ethanol producers are researching ways to reduce water use. Those efforts are paying off. The average dry mill ethanol biorefinery uses 2.7 gallons of water per gallon of production. By comparison, it takes 40 gallons of water to produce one cup of coffee; 4 gallons for a pound of hamburger; 11.6 gallons to produce a pound of chicken; and 300 million gallons to produce just one day’s worth of the newspapers across the country. (Waterfootprint.org) As the industry commercializes advanced and cellulosic ethanol, its benefits to the environment will improve further, protecting the planet and future generations.

Source : http://www.ethanolrfa.org